The AC Assembly Line we offer is an efficient and automated production solution specially designed for the air conditioning manufacturing industry. The production line integrates key modules such as pre-assembly and distribution line, vacuum line, test line and packaging line, which can meet the needs of modern air conditioning production, help enterprises greatly improve production efficiency, reduce labor costs, and ensure the quality and consistency of final products.

Main composition and function

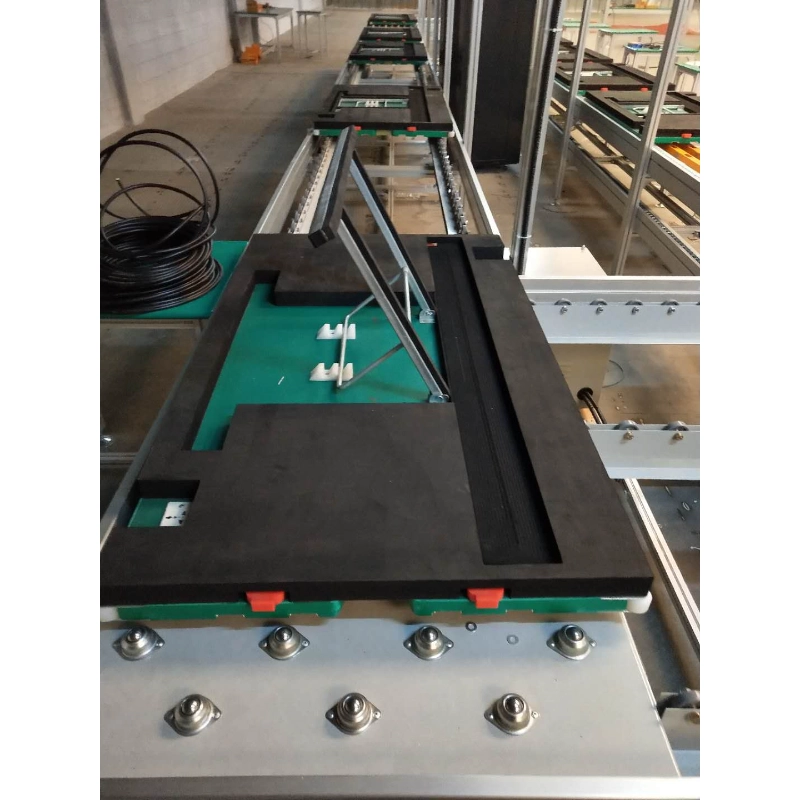

Preload wiring

Preassembly wiring is the beginning of the whole production line, mainly responsible for the initial assembly of the main components of air conditioning. This part of the equipment adopts highly automated technology, which can complete the accurate installation of compressors, circuit boards, fans and other core components. Through the advanced robot arm and automatic transmission system, the preassembled wiring can realize the parallel production of multiple models in a short period of time, ensuring the efficient circulation of products.

Vacuum pumping line

The vacuum line is the key link in the production of air conditioning, which is responsible for the vacuum treatment of the refrigeration system inside the air conditioning, so as to ensure the normal filling of refrigerant and the efficient operation of the system. The module is equipped with a sophisticated vacuum pump and control system to ensure efficient and uniform vacuum process, while reducing the impact of air and moisture on the air conditioning system, improving the long-term stability of the air conditioning.

Line of test

The test line is an important part of the comprehensive function test of air conditioning equipment, covering a number of test items such as temperature, pressure, electrical performance and noise. Through advanced test instruments and automatic detection system, it can monitor the working status of each air conditioner in real time to ensure that its performance meets the requirements of the standard. In addition, the test line adopts high-precision sensors and data acquisition system, which can accurately record the test data of each air conditioner, providing a reliable basis for subsequent quality tracking.

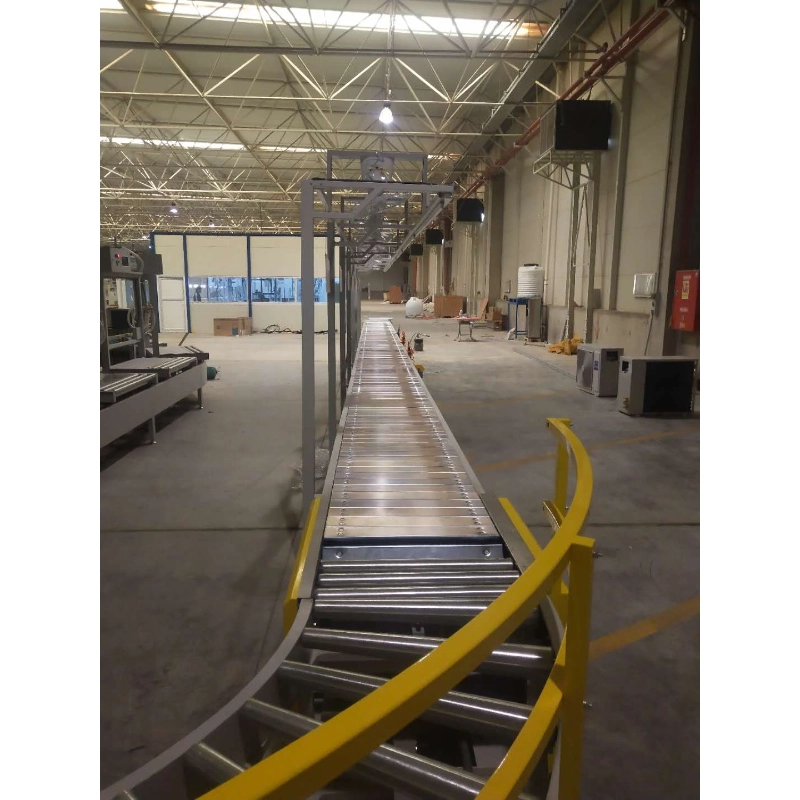

Line of packing

The packaging line is responsible for the final packaging and shipment preparation of all tested air conditioners. This part of the equipment has automatic sorting, packaging, labeling and other functions, which can effectively improve the packaging efficiency and ensure that the air conditioner is protected from damage during transportation. The packaging line can flexibly adjust the packaging method according to different air conditioner models and specifications to meet the needs of different customers.

Key Features

Reasonable layout, compact structure

The design of the whole production line focuses on the rational use of space, compact and efficient layout, optimized the connection between each link, and shortened the production cycle. Whether it is single product production or mass production, can maintain good production efficiency.

Highly automated

Robot automation technology, precision sensors and advanced control systems are widely used in the production line, which greatly improves the degree of automation in the production process, reduces manual intervention, and improves production stability and product consistency.

Adapt to multi-product production

Our AC Assembly Line is particularly suitable for the production of multi-model and multi-specification air conditioners. Through flexible process design and equipment configuration, the production line can easily switch between different production modes, support the rapid switch of internal and external air conditioning types, different sizes and different functions, and help customers achieve more efficient multi-variety production.

High quality assurance

The electrical and pneumatic components used in the whole production line are from the world's leading well-known brands, such as Schneider, Omron, Mitsubishi, Siemens, etc., to ensure that each component has high precision and long durability. The high-quality components of these brands ensure stable and efficient operation of production lines over the long term, while reducing failure rates and downtime.

Summary

Our AC Assembly Line not only has efficient production capacity and flexible multi-product adaptability, but also ensures the accuracy, stability and reliability of the air conditioning production process through first-class automation technology and the application of high-quality components. Whether it is to improve production efficiency, reduce production costs, or ensure product quality and consistency, our AC Assembly Line can provide air conditioning manufacturers with superior production solutions to help them stand out in the highly competitive market