One-stop customizable service

Turnkey project service

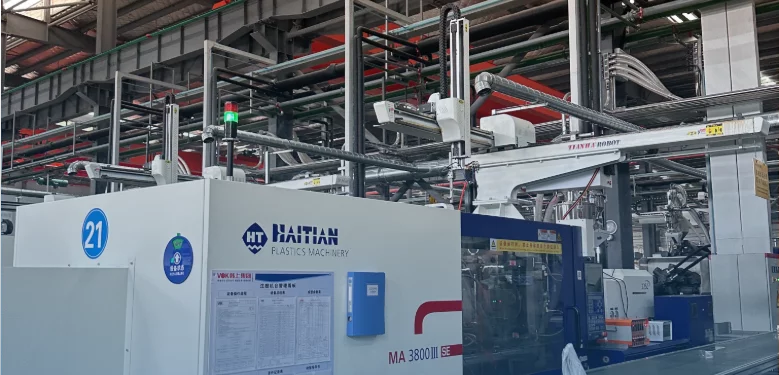

- Plan & design of household electrical appliances plants

- R&D of household electrical appliances

- Manufacturing process design

- General contract of the equipment

- Testing device supply

- SKD& CKD parts supply

- Mold design and manufacture

service Process

-

01

Customer Demand

-Market research and analysis

-Product design input

-Confirmation of the integrated solution -

02

Industrial Design

-Design strategy

-Industrial design proposal and review

-External prototype and confirmation -

03

Technical Design

-Structure design

-Cooling system design

(Transmission system design)

-Electronic controlsystem design

-Technical design review

-Product BOM and cost estimate

-Product mold investment budget -

04

Functional Prototype

-Functional prototype manufacture

-Functional prototype testing and review -

05

Mold Manufacture

-Tooling design review

-Mold flow analysis

-Mold design and manufacture

-Mold trial and final acceptance -

06

Process Design

-Process flow chart

-Process documents -

07

Standard Prototype

-Molding prototype manufacture

-Molding prototype testing and review -

08

SKD&CKD Supply

-Technicalrequirements for key compononts

-Quality control

-Package and Shipment -

09

Pilot Production and Technical Support

-Assembly process training

-Key process technical guidance

-Testing and review of trial products

-Othertesting and certification services

service Advantages

-

The whole process technical solution for customers who want to build household appliances’ plant

-

Scientific design on factory layout and manufacturing process

-

Systemic design and consideration for different models and platforms ,which can save cost and make the investment with more output value

-

Sustainable and low-cost CKD parts design and supply