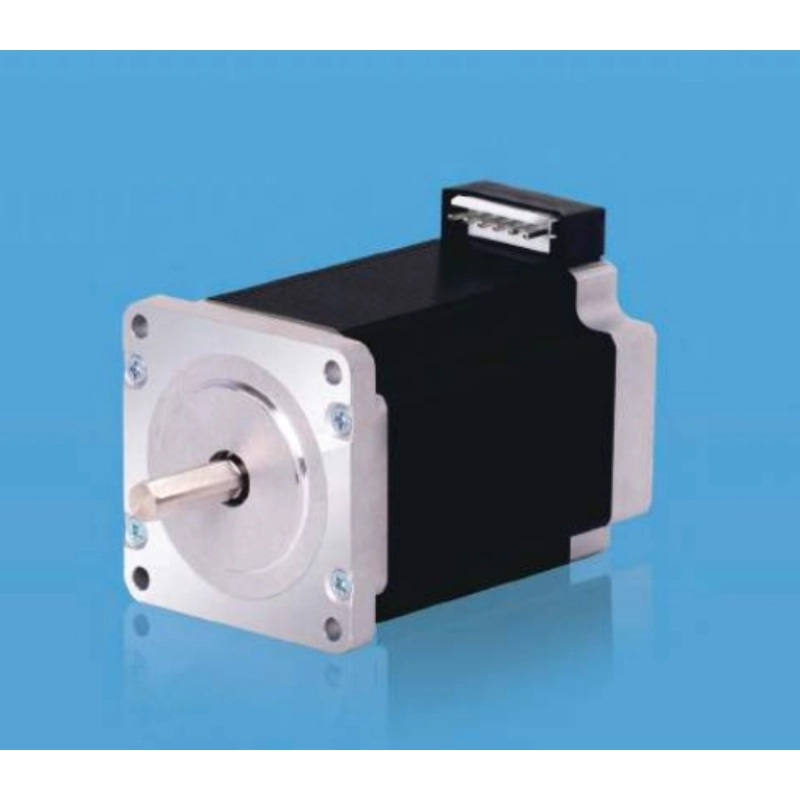

Hybrid stepper motors, brake stepper motors, reducer integrated

stepper motors, hollow shaft stepper motors

DC and AC are optional

All motors convert electrical power, volts and amps, into mechanical power, torque and speed. The unique feature of stepper motors is that they can be very accurately controlled in terms of speed and rotation angle. Stepper motors are brushless DC motors, and as such, require an electronic driver to commutate the windings. In order to control the rotation, electrical pulses are input into the driver, and the motor rotates one step for each pulse. The excellent stability of the motor results in a simple control circuit, since the motor can be run open-loop and no feedback is required.

There are three types of stepper motors; variable reluctance, permanent magnet and hybrid stepper motors. This article will focus on hybrid stepper motors as well as Oriental Motor's AlphaStep Hybrid Control System for stepper motors.Two-phase DC brake stepper motor in NEMA

17, NEMA 23 and NEMA 34

Dc and AC are available for options

High-torque, 2-phase bipolar stepper motors and geared type stepper motors offer the optimum performance and value. In addition to offering high torque, the PKP series stepper motors offer more variety of electrical specifications, more frame sizes, encoder options and electromagnetic brake options for the right solution in stepper motors.

- Offers 1.2 ~ 1.7 Time More Torque

- 1.8° (200 pulse/rev) & 0.9° (400 pulse/rev)

- Spur Gear or Planetary Gear Types

- Flat Motor types with or without Harmonic Gear available for space saving and greater inertia matching

- Bipolar (4 lead wires)

- Encoders - 200, 400 or 1000 Lines of Resolution

- Electromagnetic Brake Type

- Bipolar Stepper Motor Drivers Available

The CVD driver offers superior performance and value and is ideal for OEM or single axis machines. The CVD series stepper motor drivers offer:

- Lowest Vibration and Noise with advanced Microstepping control

- Pulse Input or RS-485 Communications Type

- Significantly improves positional accuracy when microstepping

- Highest torque with Bipolar configuration (4 lead wire)

- Small, thin microstepping drive with space saving FETs

- Selectable step angle and microstepping filter control

- 2 mounting types and connector configuration

- Alarms

- 24 VDC Input / 0.5A to 4.5A

| Available Options | Current per Phase | Lead Wires | Max. Holding Torque | ||

| Standard Type (1.8°) | Encoder | 0.5 or 0.6 A | 4 | 2.8 ~ 5.1 oz-in | 0.02 ~ 0.036 N·m |

| Standard Type (1.8°) | Encoder Electromagnetic Brake | 1.5 A | 4 | 13.4 ~ 26 oz-in | 0.095 ~ 0.19 N·m |

| Encoder | 12.2 ~ 23 oz-in | 0.086 ~ 0.165 N·m | |||

| Encoder | 42.5 ~ 112 oz-in | 0.3 ~ 0.8 N·m | |||

| Standard Type (1.8°) | Encoder Electromagnetic Brake | 0.85 ~ 1.5 A | 4 | 28 ~ 52 oz-in | 0.2 ~ 0.37 N·m |

| Standard Type (1.8°) | Encoder Electromagnetic Brake | 0.28 ~ 2.3 A | 4 | 14.2 ~ 140 oz-in | 0.1 ~ 0.99 N·m |

| 0.67 ~ 1.5 A | 42 ~ 116 oz-in | 0.3 ~ 0.82 N·m | |||

| Encoder | 1.5 or 2.3 A | 28 ~ 2,544 oz-in | 0.2 ~ 18 N·m | ||

| ① | Type of motor | Y07:Y07 series motor Y09:Y09 series motor |

||

| ② | Motor installation dimensions |

20:NEMA8 28:NEMA 11 35:NEMA14 43:NEMA 17 59:NEMA23 110:NEMA 42 130:NEMA 52 |

||

| ③ | Number of step angles | D:Hybrid sepper motor with astep angle of 1.8degree C Hybrid steppermotor with astep angle of 0.9 degree |

||

| ④ | Factory model number | 17155:Factory model number | ||

| D:Double outputshaft | ||||

| M:Additional brake installed | ||||

| E:Additional encoder installed | ||||

| LC:Outboard-driven screwmotor | ||||

| ⑤ | Motor type | GC:Through-going shaft screw motor | ||

| GD:Fixed shaft screw motor | ||||

| GZ:Ball leadscrew motor | ||||

| ZK:Hollow shaft motor | ||||

| SK:ZR shaft motion hollow motor | ||||

| ※ For product details,please visit the official website www.kaifulL.net to download 3D/2D information and the user manual. |

||||

| ① | Motor installation dimensions |

42:NEMA17 90:NEMA34 |

60:NEMA24 | |

| ② | Product code | |||

| ③ | Reduction ratio | MACR6:1:3.6 | MAGR2:1:7.2 MAA0:1:10 |

|

| MA09:1:9 | ||||

| MAA8:1:18 | MAC6:1:36 MAA00:1:100 |

|||

| MAE0:1:50 | ||||

| ④ | Serial number | |||

| ※ For productdetails,pleasevisit the official website www.kaifullnet to download 3D/2Dinformation and the user manual. |

||||

Advantages / Types of Stepper Motor

Permanent Magnet

Variable Reluctance

Hybrid

Step Angle

7.5° or larger

1.8° or smaller

1.8° or smaller

Output Torque

Moderate

Low

High

Detent Torque

Yes

No

Yes

Pulse Rate / Speed

Low

High

High

Acceleration / Response

Slow

Fast

Fast

Noise

Quiet

Loud

Quiet

Microstep

Yes

No

Yes

Design

Simple

Moderate

Complex