Our China OEM/ODM LED TV Assembly Line is an efficient and automated production line specially designed for LED TV manufacturing industry, aiming to meet the needs of high efficiency, precision and flexibility of modern TV production. The production line covers key modules such as pre-assembly and distribution line, final assembly line, test line and packaging line. It ADAPTS to diversified product models and provides efficient production solutions to help manufacturers improve production capacity, ensure product quality and reduce production costs.

Main composition and function

Preload wiring

Preassembly wiring is the beginning of LED TV production and is responsible for the initial assembly of various key components of the TV, including the display panel, backlight, motherboard and other electronic components. This part adopts advanced automation equipment and robot technology to ensure accurate and stable assembly of components, reduce manual operation and improve assembly accuracy. The automatic transmission system can efficiently transfer parts to the next process, ensuring smooth and seamless production process.

Final assembly line

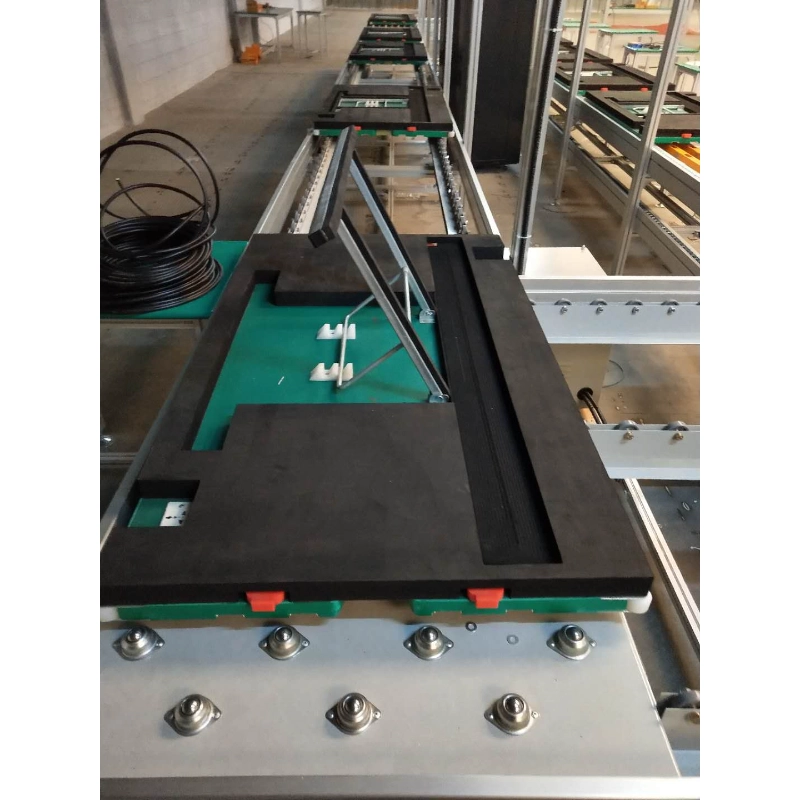

The final assembly line is responsible for the final assembly of the LED TV, including the installation of the TV case, the fixing of the LCD screen, the connection between the main board and the electronic components, and other details. The production line has a flexible workstation design that can be quickly switched according to different models and specifications of TVS, supporting the production needs of multiple varieties. Using automatic fixture and robot operation, to ensure that each TV assembly precision and efficient completion.

Line of test

Test line is the key link to ensure the quality of TV, covering display effect, function, electrical performance, stability and other testing items. Through automated test equipment, the production line can monitor the display effect, resolution, contrast, color accuracy and other indicators of each TV in real time, while also conducting a comprehensive check on the safety and stability of the electrical components. The system can automatically record test data to ensure that each factory TV meets quality standards and reduce the flow of unqualified products into the market.

Line of packing

The packaging line is responsible for the final packaging of all tested LED TVS and preparing them for shipment. This part is equipped with automatic packaging system, which can efficiently and accurately complete the TV packaging, labeling, stacking and other tasks. The packaging line can flexibly adjust the packaging mode according to different models of TV, ensuring that the TV is protected from damage during transportation, while saving packaging materials and reducing costs.

Key Features

Reasonable layout, compact structure

The design of the production line pays attention to the rational use of space and the efficient connection of each link. Through the compact layout, the entire production line can operate efficiently in a limited space, while reducing ineffective handling and waiting time, improving the overall production efficiency.

Highly automated

The production line adopts a number of advanced automation technologies, including robot assembly, automatic transmission, intelligent detection system, etc., which greatly improves the production efficiency and the stability of the production process. The improvement of automation effectively reduces the error of manual operation, reduces labor costs, and improves the consistency of production.

Adapt to multi-product production

The production line is extremely flexible and can support the production of multiple models of LED TV. Whether it is TVS of different sizes, resolutions or functions, the production line is able to quickly switch production modes with simple adjustments to meet the diverse needs of OEM and ODM customers.

High quality assurance

The electrical and pneumatic components used in the whole production line are from international famous brands, such as Schneider, Omron, Mitsubishi, Siemens, etc., to ensure the high performance and long life of the equipment. The key components of these brands ensure the stability and efficiency of the production line, ensuring that the production of each TV can be carried out in the best condition, reducing the failure rate and extending the service life of the line.

Summary

Our China OEM/ODM LED TV Assembly Line not only has a high degree of automation, flexible multi-product adaptability and compact layout design, but also ensures the efficient and stable operation of the whole production line through high-quality electrical and pneumatic components. Whether it is to improve production efficiency, ensure product quality, or reduce production costs, our LED TV production line provides TV manufacturers with comprehensive solutions to help them achieve greater success in the highly competitive market.